With the urban areas there is need to establish fish factory plants in Kisumu. Food processing enterprise 71-80.

Planning And Engineering Data 3 Fish Freezing 6 Layouts And Construction Work

For these reasons remarks and guidance on plant design are set out below Shapton and Shapton 1991 Hayes 1985 EEC.

. Up to 5000 Nova Scotians work in seafood processing plants. The dimensions and arrangement of facilities in the current plant layout was used as a guide when designing the new plant layout. Plant Layout 44-50 Lesson 8.

At seafood processing plants achieving the highest quality water standards is paramount again to prevent contamination and to attain proper moisture to keep fish products in the proper conditions. Plant layout is a plan of or the act of planning an optimum arrangement of facilities including personnel operating equipment storage space materials handling equipment and all other supporting services along with the design of the best structure to contain these facilities. 56 Food Safety - Plant Sanitation - Facility Design and Construction 23 57 Food Safety - Plant Sanitation Maintenance 24 58 Food Safety - Plant Sanitation - Cleaning and Sanitation 24 59 Food Safety - Plant Sanitation Personnel 25 510 Food Safety - Plant Sanitation Ice Water Air Gases and Steam 26.

Fish processing traditionally takes place at on-shore processing facilities and the processing of by-products on-board fishing vessels has declined during the last decades. You will probably need advice. Experimentation in Pilot Plant 59-60 Module- 5.

Basic design study report on the project for construction of kirumba fish market in mwanza in the united republic of tanzania august 2003 japan international cooperation agency overseas agro -fisheries consultants co ltd. 113 Research problem In this thesis I have investigated the potential of having a fish processing plant in Kisumu. We all depend on our experience equipment and each other to.

There also must be structured mechanisms established by local government to help recognize the needs of the fishing industry. As part of our comprehensive service to vertically integrated aquaculture operations we are capable of planning designing and constructing state-of-the-art seafood processing plants that will qualify for full certification to the latest international standards. Design equipment technological and construction projects.

AquaSol is your go-to partner for the design and installation of a world-class fish or shrimp processing plant. Capacity The installed capacity of fish processing plant is 8 lakhs tin and bottles per year. The on-farm processing facility utilized a.

It takes experience and expertise to design and equip a fish plant. Food plant layout Introduction Planning and Experimentation Lesson 7. The paths taken for each process in pasta salad production is indicated by arrows as in Fig 1.

This is especially due to the decrease of on-board fishmeal and fish-oil. The owner of the small processing plant is also often its designer because of lack of money to pay a professional consultant. Food product in a given processing plant that outlines the various steps of ensuring sanitary conditions in the plant and safety of the food product.

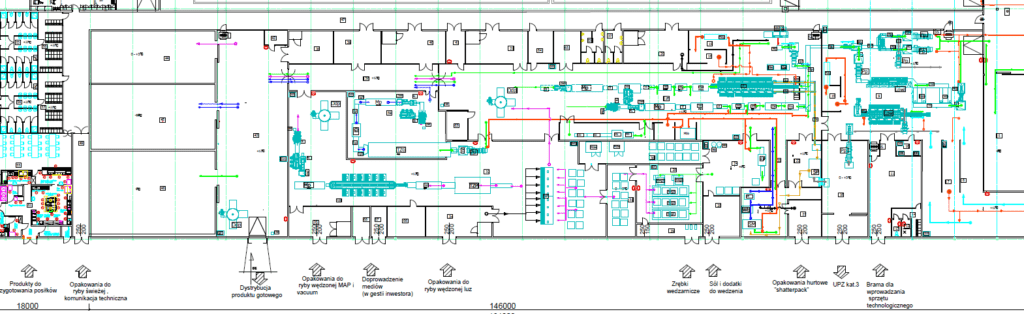

31 Layout of new food processing plant The layout of current food processing plant was first obtained from Homestyle. Figure 69 Proposed layout and flow plan for 2 tday hand-peeling shrimp processing plant. Special attention is given to the different agro-climatic conditions of Manipur so that the farmers might.

We designed processing plants from the smallest ones 26 tons per year to the huge plants with. We may consider any food processing operation as a transformation process. All of tens and tens of projects has been approved by local Vet office or other local veterinary supervision.

Where new premises are constructed. Manufacturing Process with Flow Chart Fish processing means canning of fish and prawns in brine solution to increase its shelf life. We not only understand how to meet these standards but offer our clients solutions to extend product shelf life dry and wet ice freezing and.

Enables hygienic layout design of a food-processing plant that is particularly useful in production engineering and design for food processing companies that face a. Make sure you get advice from people who understand fish processing who understand Alaska construction and fish processing regulations and who understand the special conditions in building and operating processing plants in Alaska villages. Plant layout problem is defined by Moore 1962 as follows.

DESIGN FOR A PREFABRICATED PROCESSING PLANT C-1 APPENDIX D. Symbols used for food plant design and layout 61-70 Lesson 11. The seafood processing sector is an essential part of the fishery in Nova Scotia.

Plant layout is the arrangement of equipment machines facilities in a plant for the efficient functioning of the whole system with a view to maximize the profit. The department of public health will. Facility design and requirements The basic concept of on-farm pro-cessing is a low-cost manual fish cutting operation using family or farm labor to process limited quantities of fish.

Symbols used for food plant design and layout Lesson 10. The majority of these plants are in Washington Alaska Maine Louisiana and California. Fish Processing Plants HACCP - 1 - INTRODUCTION There are a variety of potential hazards for most foods many of which can occur during the processing stage.

Figure 70 Flow chart for processing large shrimp. To demonstrate the flexibility of facility design a prototype was developed at the University of Florida. INTRODUCTION The purpose of this handbook is to help people interested in starting a fish processing.

Initially the processing plant design equipment waste management and fixture layout will be evaluated by the county public health department. The location of a smoked fish processing plant its design layout construction and equipment should be planned in detail with considerable emphasis on the hygienic aspect sanitary facilities and quality control. DESIGN FOR AN EGG PROCESSING ROOME-1.

In a fruits and vegetables processing plant the raw materials raw fruits and vegetables are transformed. Floors should be hard-wearing non-porous washable well drained non-slip and resistant to possible attack from brine weak ammonia. Some processing occurs in Delaware Florida Illinois Maryland New York and Virginia.

9131 Fish Processing 91311 General Fish canning and byproduct manufacturing are conducted in 136 plants in 12 states. Layout Design Procedure 51-58 Lesson 9. Figure 72 Proposed layout for whole fish freezing.

Download full-text PDF Read. This hand book identified the main issues and trend in fish pond design and construction. Our processing plant workers have a long and distinguished history but their history has also had many tragedies through workplace injuries.

SAMPLE LAYOUT FOR A FISH PROCESSING PLANT. Since most fish processing plants are capable of processing high volumes of products foodborne outbreaks can potentially affect large sectors of the population. Cutlets fish pickles and prawns pickle are prepared using canned fishprawns.

Figure 71 Flow chart for whole fish freezing. ForFish Company has years of experience in design and construction process of fish processing manufactures.

Pdf Modelling And Simulation Of A Fish Processing Factory Ship Semantic Scholar

Planning And Engineering Data 3 Fish Freezing 6 Layouts And Construction Work

Fish Processing Plants Design Equipment Technological And Construction Projects

Planning And Engineering Data 3 Fish Freezing 6 Layouts And Construction Work

Fish Processing Plants Design Equipment Technological And Construction Projects

Establishments And Production Demands For Freshwater Fish Processing

Planning And Engineering Data 3 Fish Freezing 6 Layouts And Construction Work

Planning And Engineering Data 3 Fish Freezing 6 Layouts And Construction Work

0 comments

Post a Comment